HOME

LEGACY

CONTACTS

1

2

3

Ralph J. Jacob founded Vulcan Machinery Corporation in 1966 as Frank Eddy Machine Company, a valued supplier of electrical, mechanical, fabricated and machined components for the thriving tire and rubber industry in Akron, Ohio. As the polymer industry grew out of tire manufacturing industry, Ralph saw the opportunity to start the designing and manufacturing of extrusion machinery to advance the plastic industry.

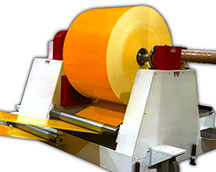

Vulcan's roots started in 1970 with the design and manufacturing of downstream sheet equipment followed by the successful production of some of the most innovative tubing and profile systems that still serve the industry to this day.

After continuous growth through the years, in 1986 Bradley Jacob joined Vulcan Machinery Corporation and continued its tradition of innovative designs for downstream plastic equipment. One of his most notable accomplishments was the design and build of a direct drive puller, which serves as the model for the modern approach of direct driven pullers. In 1991, twin brother David joined Vulcan to assist in managing of the rapid expansion Vulcan was experiencing.

In 1994, David assumed the role of president, allowing Ralph to begin pursuing interests beyond Vulcan including spending time with his many grandchildren and immersing himself in charitable opportunities including being one of the founders of the Ardmore Foundation who's mission is to support the treatment and care in a home environment for adults with developmental disabilities. in 1997, his twin sons purchased Vulcan.

Vulcan realized that servo technology had reached a point where it could be successfully implemented across all of Vulcan’s product lines. This resulted is unprecedented accuracy and reliability with drastic improvements in human/machine coordination. By 2001, Vulcan’s entire machine offerings were based on servo technology. In 2007, Vulcan revamped its servo platform further improving performance and productivity at a substantial reduction in costs, whether associated with the acquisition of new equipment or the long term ownership of it.

We use customer-specific servo controllers/drives to be used allowing our customers unprecedented flexibility in supporting their 24/7 operations. Vulcan continues to design, fabricate, machine and build all aspects of our equipment. We do not source out components or subsystems; a full service manufacturer and not just an assembler. We supply our machinery and systems with unparalleled documentation, allowing our customer the ability to decide where they secure critical support in maintaining their production in a timely and cost effective manner.

Engineering Makes The Difference

© 2020